Our Solutions

O

N

L

I

N

E

C

L

E

A

N

I

N

G

T E C H N O L O G I E S

T E C H N O L O G I E S

Our high velocity Patented Linear Cleaning method is the only solution to provide a full online cleaning service without the need to shut down or stop.

Using this method, not only are the blockages in the gas lanes cleared, but thermal efficiency can be increased by up to 110% – this means greater throughput and increased revenue for the plant.

The shockwave is precise, with just enough energy to dislodge and break up ash deposits, without affecting the plant’s integrity. Due to the targeted manner of the process the complete area or tube bundle can be cleaned, enabling OCT to offer performance guarantees should the client require this.

Why this method?

This method offers guaranteed results, unlike any other service available, largely because of the velocity of shockwaves administered.

The velocity of the shockwaves administered by this method sets us apart from the competition as our Patented Linear system produces a shockwave at a velocity of around 7000 metres/second – greater than anything offered by our competitors.

A greater velocity shockwave makes for a much more effective clean as the ash is dislodged and broken into smaller pieces which are easily cleared.

Slower velocity shockwaves, e.g. those from a gas explosion, can lead to larger deposits being stuck in tube bundles, which can then lead to a rapid blocking of boilers as well as the ash conveyor system having more blockages.

So, using PLC, plant performance can be maintained without any impact from fouling or blockages. This enables plants to extend running periods to up to two years, reducing maintenance costs and increasing availability. High temperature corrosion can also be reduced by maintaining lower flue gas temperatures at the level of the superheaters.

- Guaranteed results

- Plant performance can be maintained

- No blockages

- Reduce high temperature corrosion

- Reduced boiler fouling

- Extended running periods

- Reduced maintenance costs

- Increased availability

- Increased profit

How It Works

- If deemed necessary or if requested we will use our High Temperature, High Definition camera to determine the fouling area.

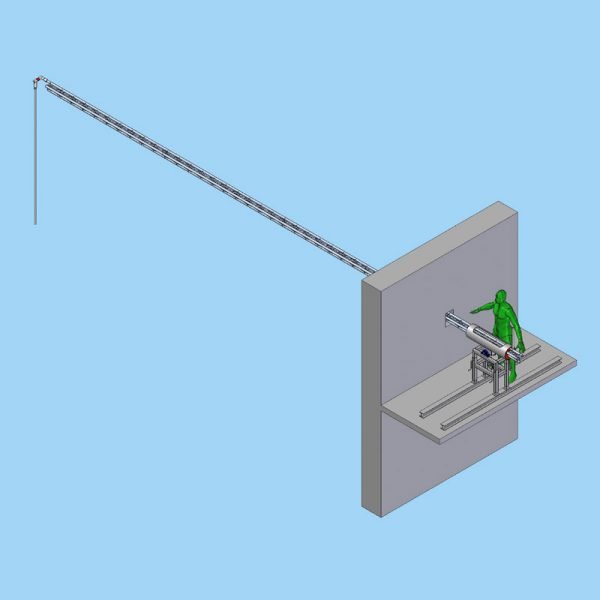

- From the boiler openings, small charges are directed via cooled lances to the fouled area of the boiler or furnace.

- The shockwave cleaning charge is positioned, via specially-designed cooled lances at the determined location (i.e. super-heater or economiser).

- Each lance has a 90-degree swivel head at its end.

- Using small, controlled, precision shockwaves, the deposits are fractured from fouled surfaces without disturbing the unit’s integrity.

- The whole system is WIFI controlled to ensure safety throughout.

- This process is repeated in grid patterns and at different elevations until the cleaning objective is met.

Why this method?

- PLC is the proven solution for up to 200 installations worldwide.

- Clean bundles up to six metres deep, even in the flue gas lines.

- Longer bundles of up to 12 metres deep can be cleaned, with lances custom-made for specific jobs.

- Efficiency can be increased by up to 110%, meaning increased revenue.

- Safer and more sustainable than traditional methods.

Applicable Sectors