Our Solutions

O

N

L

I

N

E

C

L

E

A

N

I

N

G

T E C H N O L O G I E S

T E C H N O L O G I E S

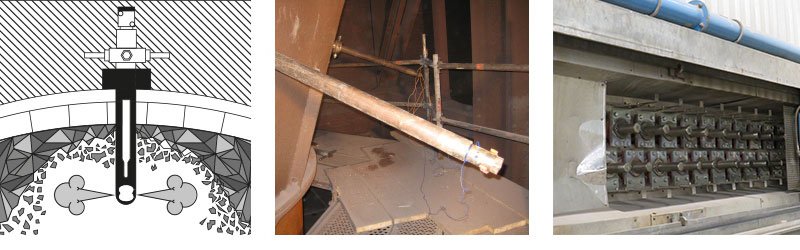

This method, which can be administered online or offline, involves inserting a compressed gas tube directly into the build-up that you want to remove.

It is suitable for use in furnaces, silos, ash pits, hoppers, tube bundles, metal smelters, economisers and coal bunkers. CO2 is an inert gas so is fire inhibiting, making this method a preferred option for certain types of blockages within coal bunkers. CO2 can also be used in the bunkers, boilers and hoppers of EfW plants. It is faster and safer than manual cleaning or vacuuming and can be used while the plant remains in full operation.

Why this method?

- Can be operated and repeated while the facility remains in operation.

- Proven solution for more than 50 installations worldwide and is most suited to heat exchangers, funnels and combustion chambers.

- Can increase efficiency from 40% to 75%.

- Can be carried out 24 hours a day, seven days a week.

How It Works

- Tubes containing liquid CO2 are inserted by fitting coupling systems to suitable areas, such as the facility’s steel casing.

- Inserting the tube through the hole in the coupling system keeps the discharge nozzle a safe distance away from the facility’s cladding.

- Once the coupling system has the tube firmly in place, an electric charge is administered, turning the liquid CO2 to gas increasing the volume and pressure. The targeted discharge of compressed CO2 from the gas tube dislodges the build-up.

- Each blast can release between 150 to 600 litres of CO2 gas at pressures between 1500 and 2700 bar. The reaction time for the process is approximately 40 milliseconds.